2 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

Whether protecting crops from diseases and pests or sanitizing contaminated surfaces, the ability to spray protective chemicals over important resources is key to several industries. Electrostatic Spraying Systems Inc. (ESS) of Watkinsville, Georgia, manufactures electrostatic sprayers and equipment that make this possible. By licensing NASA electrostatic technology, originally made to water plants in space, ESS’s improved spray nozzles efficiently use basic laws of electricity to achieve complete coverage on targeted surfaces.

ESS traces its origins to research done at the University of Georgia in the 1970s and ’80s. An electrostatic sprayer works by inducing an electric charge onto atomized droplets. Much like an inflated balloon sticking to a wall when it’s gained a charge of static electricity, the droplets then stick to targeted surfaces.

NASA’s interest in this technology originated with astronauts’ need for an easy way to support plant-growth experiments in space. On the International Space Station, watering plants without the help of gravity isn’t as easy as using a garden hose on Earth. In the future, using a system like an electrostatic sprayer on the space station or other orbiting destination could help the water droplets stick to the plants with uniform coverage. However, most spraying systems require large sources of water and air to properly aerosolize fluids.

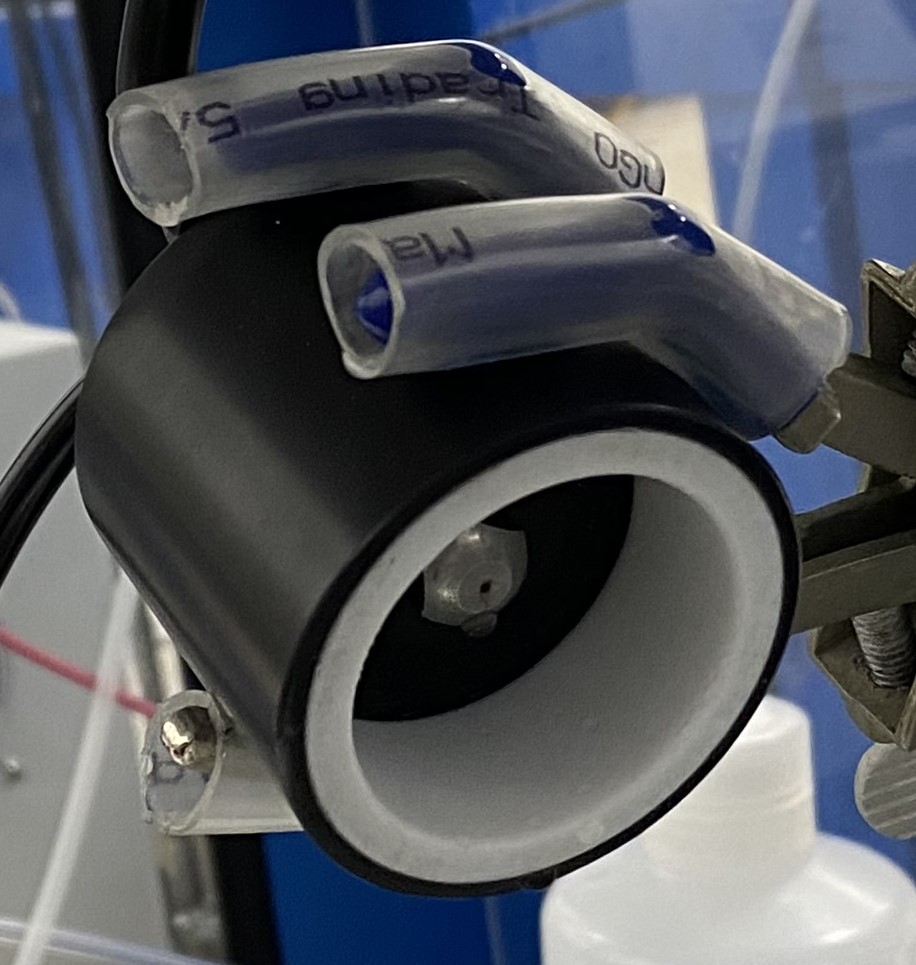

As both air and water are precious resources in space, NASA needed an easier way to make these incredibly small droplets. Charles Buhler and Jerry Wang of NASA’s Kennedy Space Center in Florida led the efforts to develop this capability, with Edward Law of the University of Georgia as a consulting expert. Eventually, the NASA team developed a new design by learning from existing technology called a mister nozzle. The benefit of a mister is that even though the interior volume of the nozzle is small, the pressure inside never builds up, which makes it perfect for enclosed small spaces like the space station.

As the sprayer industry is a tight-knit group, technology transfer professionals at NASA reached out to the companies that could use a nozzle like this on Earth. Electrostatic Spraying Systems responded and later licensed the sprayer design from the agency and incorporated it into the company’s Maxcharge product lines.

Share

Details

Related Terms

Discover Related Topics