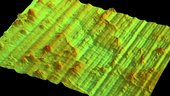

A microscopic-3D image of a small area of an ‘off the shelf’ gold coated mirror, produced through diamond-turning. The largest feature size is about 30 nm high and the average roughness of the surface is about 10 nm. For a commercial product this is a satisfactory result for ESA to utilise. The quality of this mirror surface was tested at ESA’s optics laboratory to verify that its performance and quality was sufficient for use in a laser communications experiment. The vertical lines running from top to bottom along the surface are an expected characteristic of the process used to manufacture the mirror.

This mirror was installed in ESA’s optical ground station (OGS) on the Canary Islands (Spain) and successfully used in the recent test campaign with NASA to verify the performance of their new laser terminal on the Lunar Atmosphere and Dust Explorer (LADEE) spacecraft orbiting the moon.